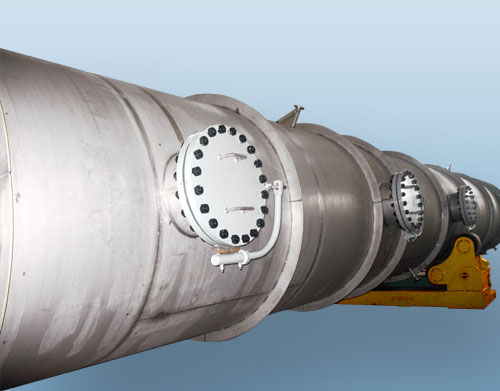

Stainless Steel Tower Vessel

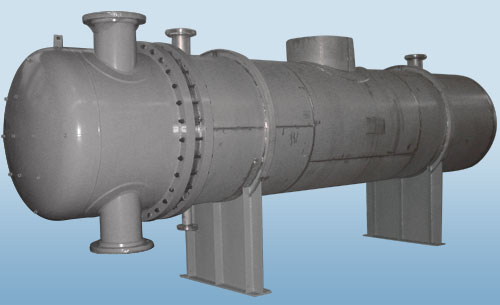

He-Huang

Chemical Equipment

Tower equipment is one of the most important unit operations in chemical production. It enables full contact between gas (vapor)-liquid phases or liquid-liquid phases through its internal structure to achieve mass transfer and heat transfer. Unit operations completed by tower equipment include distillation, absorption, desorption, extraction, washing, cooling, and gas humidification, etc.

Tower equipment is classified into plate towers, packed towers, etc., based on their internal structures. A plate tower is equipped with a certain number of trays. Gas enters the tower body from the lower part, and liquid enters from the top; the rising gas and descending liquid conduct mass transfer on each tray. A packed tower contains a packing layer of a certain height, which can be divided into several sections if a higher packing layer is required. Liquid flows downward in a film form along the packing surface, while gas passes upward through the packing layer to contact the film-like liquid for mass transfer. Tower packings are divided into two categories: random packings and structured packings. Random packings are mainly made of metal, plastic, and ceramics; structured packings are mainly made of thin metal plates, wire meshes, and plastic wire meshes.